Technology to reduce water use in textile sector

The Indian Institute of Technology, Ropar, has developed an innovative green technology — air nano bubble — that can reduce the use of water up to 90 per cent in textile industry. Nearly 200 litres of water is required to process 1 kg of cotton fabric.

The Indian Institute of Technology, Ropar, has developed an innovative green technology — air nano bubble — that can reduce the use of water up to 90 per cent in textile industry. Nearly 200 litres of water is required to process 1 kg of cotton fabric.

The laboratory reports suggest the air nano bubble dispersed in water could reduce the water consumption and chemical dosage by 90-95 per cent. -

February 06, 2023 This ultimately also saves 90 per cent of the energy consumption, said Dr Neelkanth Nirmalkar, who has developed the technology.

IIT Ropar director Rajeev Ahuja said, “eco-friendly technology has been developed at the IIT, Ropar, under a startup which is also working towards cleaning the environment and is expanding in developing new applications ranging from water treatment to healthcare.”

In the textile industry, the water is used at many steps, including for dyeing, finishing chemicals in the textile substrates, desizing (process of removal of sizing material from yarn), scouring, bleaching, and mercerizing (chemical treatment of fabric to enhance affinity towards dye).

At the same time, the textile industry also produces the highest volume of waste water.

Dr Nirmalkar said the technology was based on nano bubbles of air and ozone.

Most viewed

- Amid weak demand, cotton price surge adds to woes of yarn mills

- Centre willing to procure jute and cotton crop if prices fall below MSP : Goyal

- BTMA signals minimum wage structure for cotton textile sector within next two weeks

- ASEAN delegation to visit India on 17 Feb for FTA review

- State further subsidises power supply to textile industry till 2028

- Bank fraud case: Textile baron Neeraj Saluja sent to 5-day police remand

- New MSME payment rule leads to many cancelled orders

- Boosting trade relations with India

- India’s cotton yarn exports to surge by 85-90% in FY2024: ICRA

- Bhiwandi Textile Firm Owner Flees After Duping 13 Manufacturers of Rs 58.55 Lakh

Short Message Board

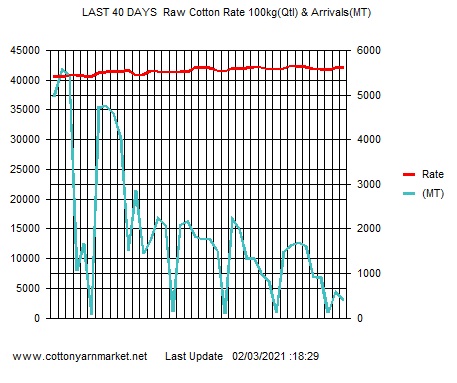

Cotton Live Reports

Visiter's Status

Visiter No. 31719628Saying...........

Misfortune: the kind of fortune that never misses.

Tweets by cotton_yarn